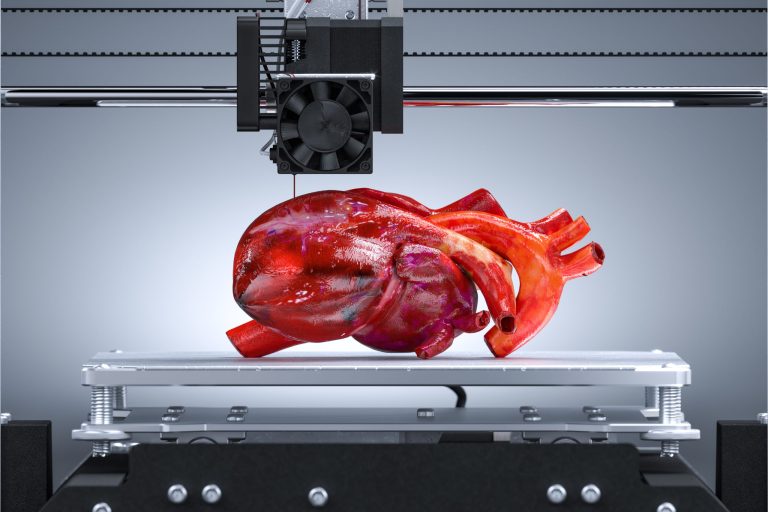

Latest News: ABCorp 3D Receives ISO 13485 Medical Device Certification. Learn More.

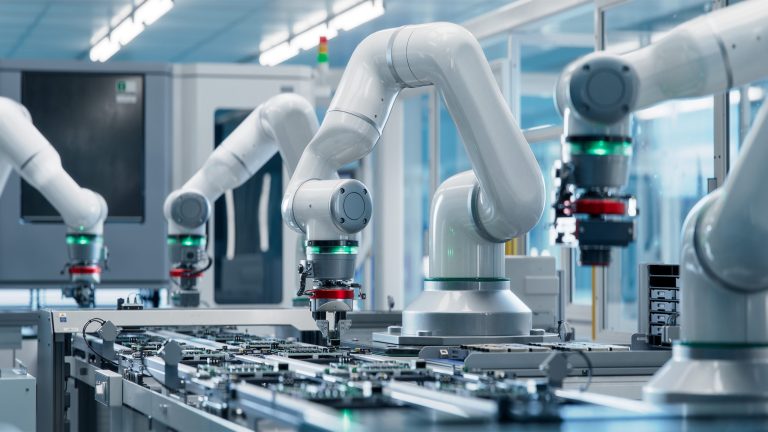

3D Printing and Robotics: The Future is Now

In recent years, we have witnessed a paradigm shift in the way we think about, create, and produce robotic parts — all thanks to the radical advancements in 3D printing technology.