Recently I came across a website encouraging consumers and businesses to “Buy American” products. The website is a group of retailers, trade organizations, and service providers dedicated to sharing the message of bringing jobs and manufacturing back to American soil.

Recently I came across a website encouraging consumers and businesses to “Buy American” products. The website is a group of retailers, trade organizations, and service providers dedicated to sharing the message of bringing jobs and manufacturing back to American soil.

It reminded me of my early years in construction material sales. Back then the requirement was called the “Buy America Act” and it required all (with some exemptions) construction products used in public buildings to be made in the United States. The Act caused manufacturers, suppliers and architects to source domestically made products for their customers and projects. As with all market forces, things change, costs go up, higher inventory levels are required, and a tighter workforce requires the outsourcing of domestically made products — better known as offshoring.

A more recent market force was the COVID-19 pandemic, which exposed weaknesses in our supply chain for manufactured goods as well as raw materials. When the supply chain finally did start to open, it was in slow motion with lengthy leads times being the norm, causing trickle down effects to numerous industries. As examples, we witnessed a single out-of-stock part cause delivery delays of fleets of automobiles, and limited supplies of RFID chips put a stranglehold on the tech industry.

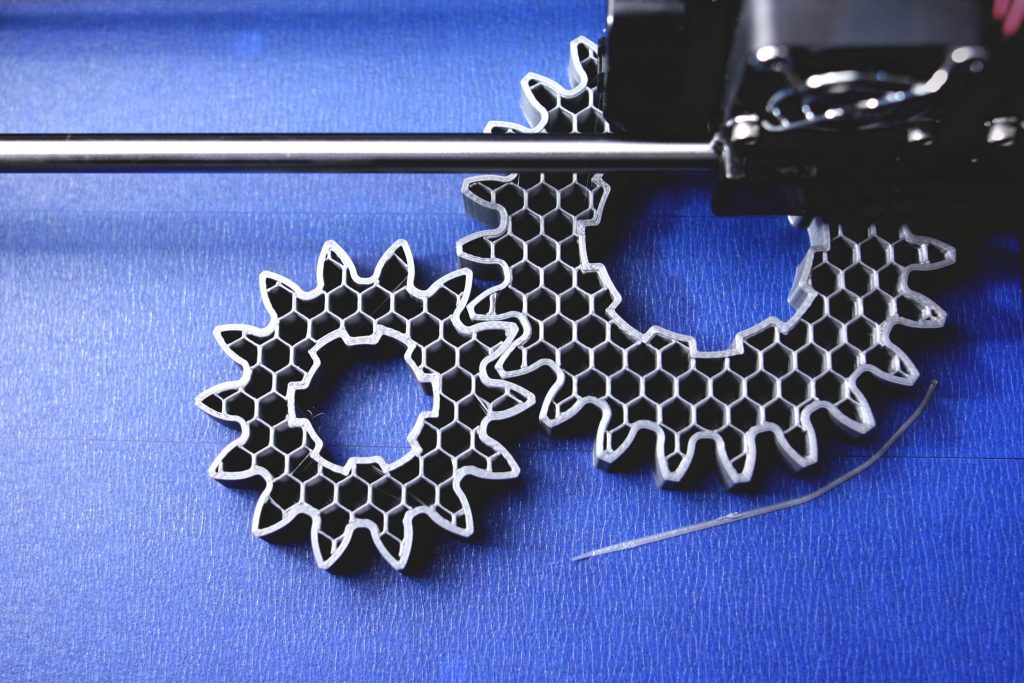

Additive Manufacturing, or 3D Printing, can reverse offshoring and bring manufacturing back to America. Additionally, it has the power to energize smaller local businesses as the Additive Manufacturing market grows and develops. Start-up business can afford to run limited quantities of products as they develop the market or make changes to parts as their market changes. At the recent AMUG 2023 event in Chicago, I noticed a broader scope of interest in 3D Printing of those in attendance, such as smaller businesses that specialize in tool path optimization or stronger finishes for unique applications.

Printing processes and materials are becoming more niched to a segment or product type. Gone are the thoughts of replacing traditional manufacturing with all things 3D Printed, replaced with a working “with it” attitude to help transform and grow in the new Industry 4.0 marketplace.

What is Industry 4.0? It can be defined as the integration of intelligent digital technologies into manufacturing and industrial processes. One of the first steps in this process is automation. Evaluating and creating a digital inventory of parts in your supply chain will help identify what parts are best for 3D Printing, while having a digital file of a needed part gives flexibility to choose the best material and printing process. All printing processes are not the same, as part geometry or end use requirements may dictate a specific printing process or material.

A good example is Fused Deposition Modeling (FDM) vs Multi Jet Fusion (MJF). With FDM, geometry of the part dictates the length of print time due to support generation during the print. Alternately, MJF is a system that uses powder to support the model during the printing process which results in a set printing time per build. Additionally, multiple parts can be nested in a full print build to further bring down the printing cost per part. Note that not all printers are efficient at printing quality end use parts and very few can do it at scale.

Print processes like MJF work well for the large manufacture for complex assemblies as well as the creation of prototypes for small businesses as they introduce new parts. The HP MJF system has been designed to print multiple part runs with support equipment to automate the process.

Print processes like MJF work well for the large manufacture for complex assemblies as well as the creation of prototypes for small businesses as they introduce new parts. The HP MJF system has been designed to print multiple part runs with support equipment to automate the process.

ABCorp has been a secure contract manufacture since 1795, creating the first anti-counterfeit currency for the United States. As markets change, we now create and manufacture a good portion of the world’s plastic credit cards, government passports, and gift cards. When COVID hit, our punch presses transitioned to face masks and we ventured into Additive Manufacturing to help address the tightening supply chain concerns.

In a short time, ABCorp-3D has grown to house multiple HP MJF 580 and 5210 series printers in our secure Boston facility. Our current material offerings are Nylon PA-11, PA-12, Polypropylene, and BASF Ultrasint TPU. The HP 580 creates colors parts in Nylon PA-12CB material.

If you’re in a position to review your parts for a digital inventory or would like us to print a few parts, please reach out to us. A CAD file with an .stl or 3MF file along with design specifications is enough to start the conversation. Samples available upon request.

For additional information, please feel free to email us at 3d@abcorp.com.

Vic Little

Vic Little

Business Development

ABCorp-3D