In recent years, we have witnessed a paradigm shift in the way we think about, create, and produce robotic parts — all thanks to the radical advancements in 3D printing technology. This shift has not only pushed the boundaries of what was once deemed possible, but has started a revolution across industries, promising a world of opportunities to better our lives in ways that were once thought to be unattainable.

The Current State of 3D Printing in Robotics

Before we embark on a journey into the future, let’s take a beat to reflect on the current state of 3D printing within the robotics realm.

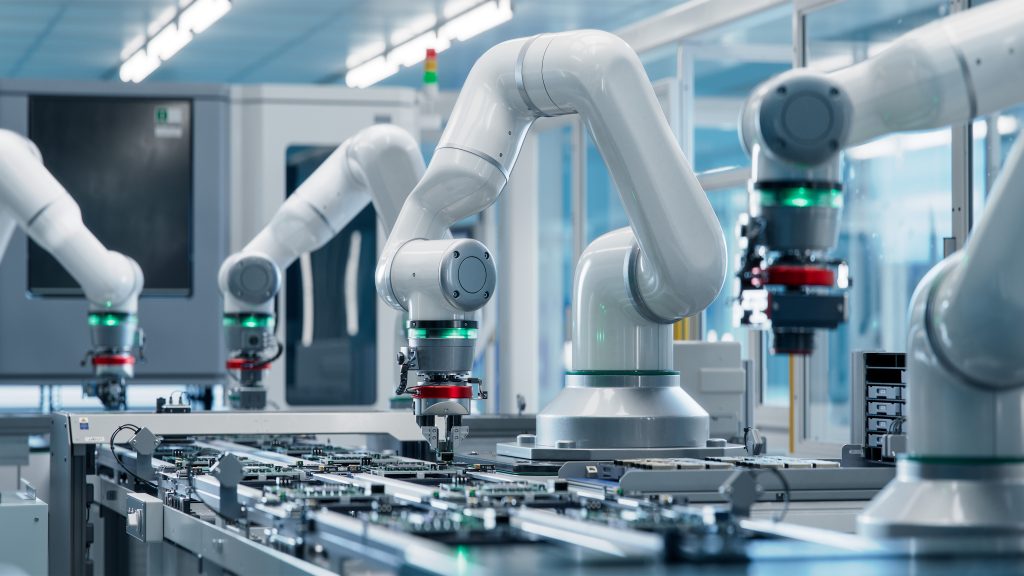

There’s no denying that 3D printing has made significant strides in the robotics field (and beyond) these past few years, cultivating a newfound sense of creativity that has led to the creation of intricate, innovative, and fully customized components. It’s also worth mentioning that one of the more notable benefits of 3D printing in robotics has been the ability to improve the production of these complex geometries that would otherwise be challenging, if not impossible, to achieve through more traditional manufacturing methods.

Material World

Looking ahead, the future of 3D printing in robotics is, without a doubt, going to be defined by a significant leap in material innovation and customization. As 3D printing technologies continue to rapidly advance, we can expect a much broader range of materials to become available for robotic fabrication, one of which being soft robotics.

Soft robots, made up of flexible and compliant materials, are quickly finding their way towards more diverse fields, from medical devices to search and rescue missions. 3D printing allows for the fabrication of intricate, soft robotic components that are able to seamlessly blend in with their rigid structure counterparts, allowing robots to navigate more diverse and complicated environments with a special degree of delicacy.

This future shift will allow designers to not only tailor the mechanical properties of their components to fit these more specific applications, but to also “kick the door wide open” to unprecedented levels of performance and efficiency, allowing for innovations like multi-material printing, bio-inspired structures, and AI-driven design optimization.

As one might expect, customization — a trademark of 3D printing — will continue to play an essential role in shaping the new world of robotics. Robots are often positioned in more diverse environments and faced with unique challenges, so customization becomes a lifeline when addressing more highly specific needs. With 3D printing, robotic components can be designed and produced with laser-level precision, taking into account the various intricacies of the projects they are assigned.

This high level of customization has the potential to elevate robotic systems from the basic, more standardized tools to innovative, highly specialized solutions, and is set to unlock new frontiers in the engineering and design worlds.

Medical Field

One of the most captivating promises of 3D printing robotics lies within the realm of medical technology. Imagine a future where 3D printed robotics pave the way towards the creation of customized medical implants, meticulously tailored to suit patients’ unique anatomies and needs. It’s this level of personalization that could mark a significant jump forward in the field of healthcare. After all, 3D printed customized pharmaceuticals are already a part of our reality.

Now traditionally speaking, prosthetics and robotic hands have long faced challenges when attempting to mimic the complexities of the human anatomy, especially when it comes to prosthetic hands, which are often forced to rely on simplified designs.

Now enter 3D printing, a technology that has shattered these limitations, introducing a paradigm shift in the process.

Robot Prosthetics

Engineers now have the capability to harness the precision of 3D printing to recreate hands with individual bones, ligaments, and tendons, bringing a whole new level of detail and functionality that once seemed virtually impossible. With 3D printing, engineers can replicate bone structures and ligaments with ease, creating robotic hands that move with the same fluidity and grace of their biological counterparts.

These 3D printed hands not only look remarkably lifelike but also provide their users with a natural range of motion and sensory feedback, and enhanced sensory feedback — an aspect that is lacking in most prosthetics — as well as the prospect of a future where those with limb differences experience a level of functionality and immersion they previously did not have.

Wearable Robotics

Wearable robotics, otherwise known as an exoskeleton, are a wearable mechanism or suit that is used as a tool during physical rehabilitation. Wearable robotics help patients in relearning skills as they are able to reduce energy consumption and streamline repetitive tasks. Additionally, in many military applications, exoskeletons have proven to be an instrumental tool in helping soldiers carry heavier loads over long distances.

Wearable robotics are made possible by the lightweight and customizable nature of 3D printing, carrying uses that transcend far beyond healthcare, assisting individuals with mobility challenges or enhancing performance in various physical activities. These wearable advances might not only improve the quality of life for their users, but also open up to a world of new possibilities in fields such as sports and rehabilitation.

Conclusion

In conclusion, the future of 3D printing within the robotics world is set to be quite the game-changer (for lack of a better term) sculpting a future that was once confined to the realm of science fiction. The intricate and delicate craftsmanship of 3D printed hands with bones and ligaments, coupled with the soft robotics revolution, showcases the transformative potential of this kind of technology. And as we continue to navigate the uncharted territories of 3D printed robotics, the only certainty we do have is that the future holds a world of innovation.